Chirala Handloom Cluster

During the final year of my graduation (2016-17), I had an amazing opportunity to explore one of the remotest villages in Andhra Pradesh, Chirala. I had picked up a project in Handloom sector for one of my course and got chance to visit this coastal village multiple times for carrying out my research. Here I have documented my understanding of few of the integral processes of handloom operation.

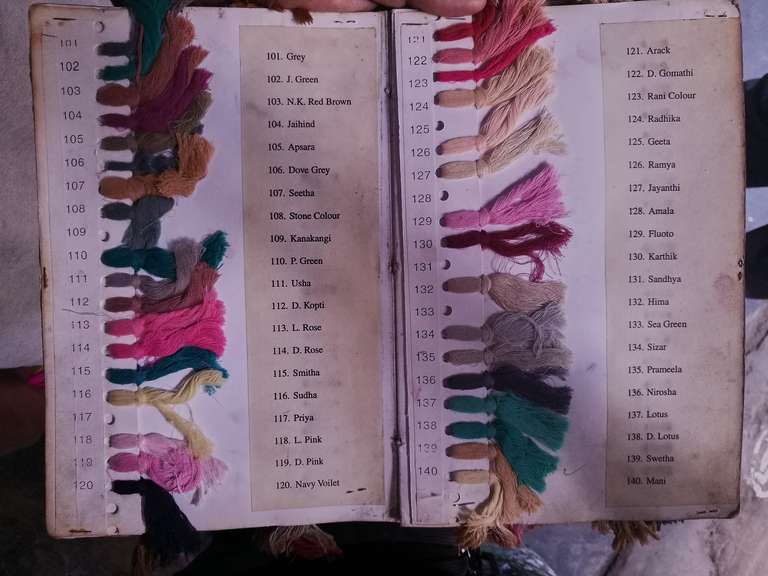

Dyeing

The cluster purchases the bales of unbleached raw cotton yarn, which is dyed in the colors demanded by the master weavers.

Street sizing

Dyed yarn goes into the next step, which is street sizing. Sizing is basically coating of the yarn with rice starch and coconut oil, to straighten the yarns and to give it temporary strength so that it can withstand the rigor of weaving in the loom. When the fabric is weaved, just a simple washing of the fabric will remove all the sizing material, giving cotton its characteristic breathability.

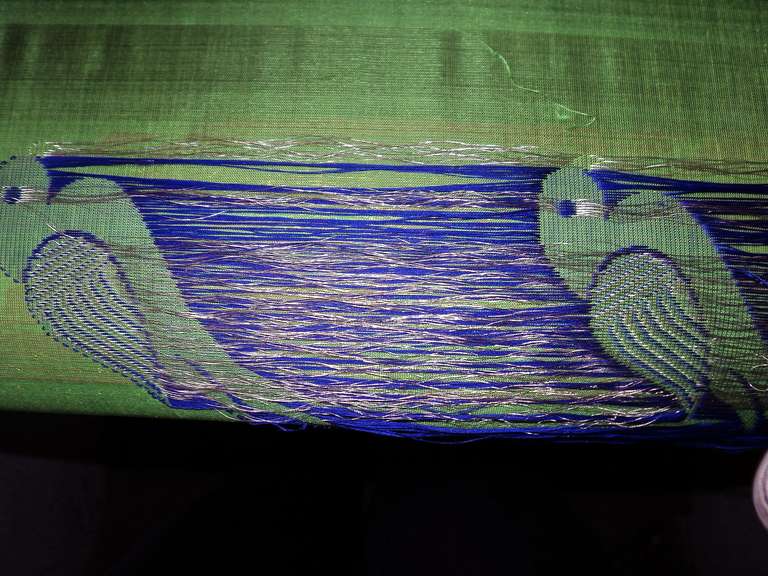

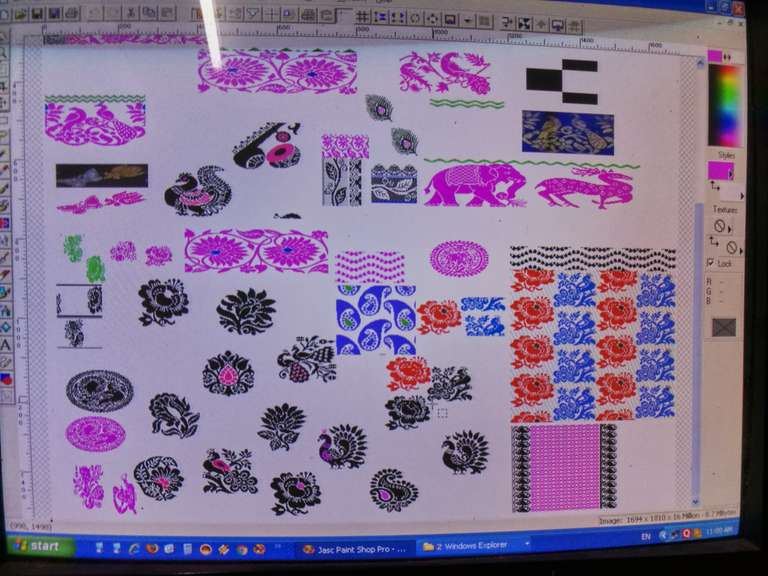

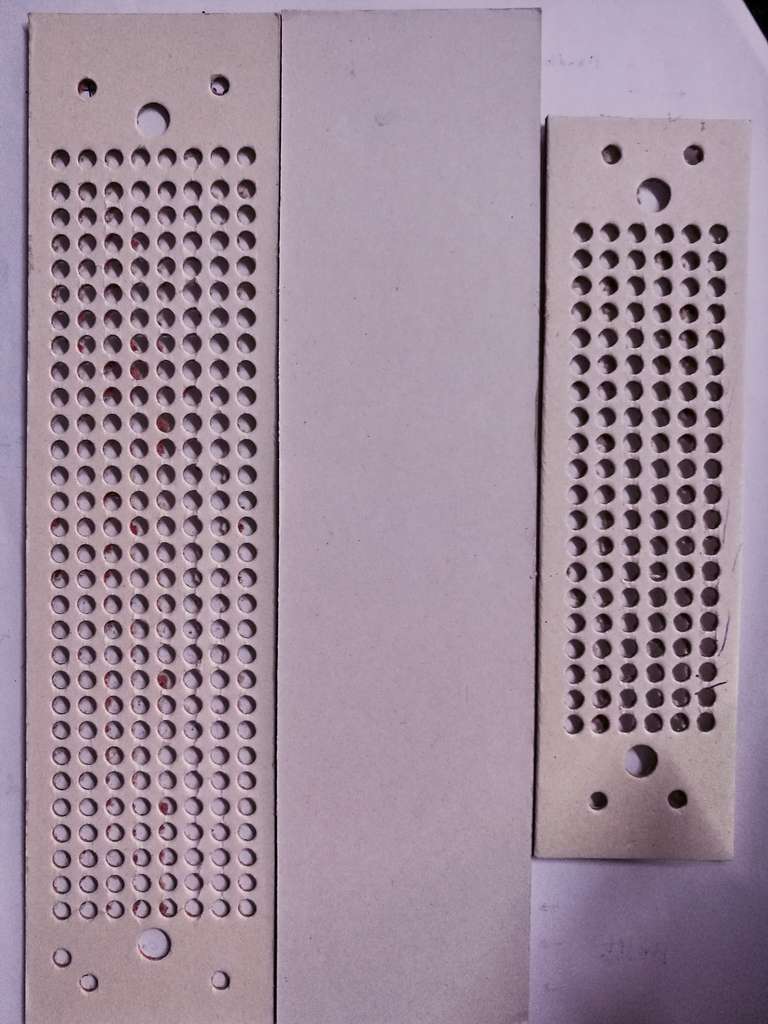

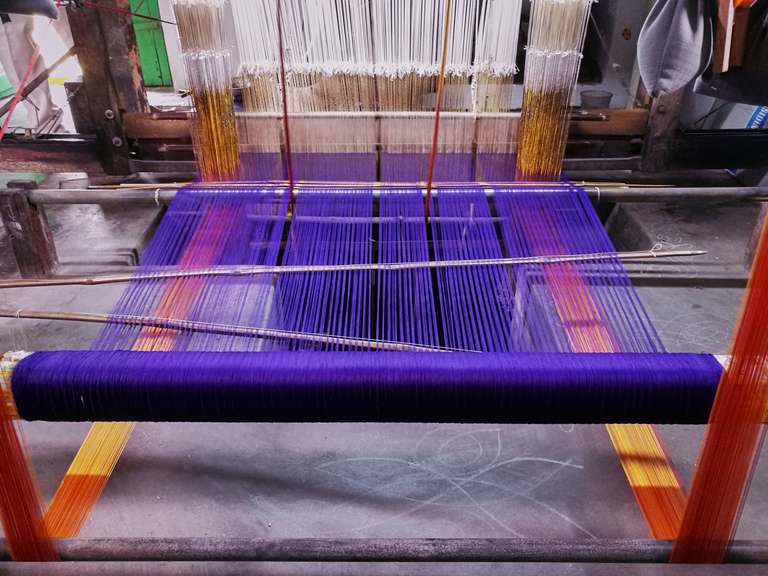

Weaving

The final process is the process of weaving. While there are a lot of types on looms used in handloom, in Chirala, pit loom is most commonly used loom. It is set up inside the houses of weavers by digging a pit into the floor, half of the loom is set into the floor, while other half is set above the floor and ceiling.